3D Scan Models are not only used, but they are also very important and necessary for modern workflows for designing, making, and maintaining car parts. The ability to quickly and accurately capture the complicated, often organic shapes of vehicle parts, body panels, and whole assemblies turns a physical object into a digital asset that can be used. Companies like 3DeVOK offer integrated scanning and software solutions that let automotive engineers use 3D Scan Models for important tasks throughout the vehicle’s life cycle, from the first idea to support at the end of its life. There are four main ways that 3D scanned models can be used in the automotive industry: reverse engineering, quality assurance, aftermarket customization, and digital archiving.

Recreating old parts and reverse engineering

In the automotive industry, reverse engineering is an important use of 3D scan models. This is especially true for classic, low-volume, or specialized vehicles where the original design documents are often missing or out of date.

The first step is to use a high-accuracy 3D scanner to digitize a physical part and make a detailed mesh. Then, this raw scan data is brought into special software that turns it into a CAD model that is based on features and parameters. Engineers take geometric primitives and use them to make an accurate digital copy by putting together complex free-form surfaces.

This method does more than just copy things; it also allows for design improvements, like better materials, stronger structures, or changes to make them work better with modern manufacturing methods like additive or CNC machining. It helps maintain older vehicles and makes sure that parts are available even after the OEM’s life cycle ends. Also, reverse engineering competitor parts gives you useful information for comparing and improving designs for the next generation.

High-Tolerance Quality Control and Measurement

In the making of cars, strict quality control is necessary to meet strict dimensional tolerances for safety and performance. 3D scan models are now an important part of modern metrology. They are much better than older tools like CMMs, which only capture a few discrete points.

A new part, like an engine casting or a mold, is fully digitized using high-resolution 3D scanning. Then, inspection software uses math to compare the scan data to the original CAD design. The system makes a color-coded map that shows geometric differences across millions of points using deviation analysis. This quickly shows problems like warping, shrinkage, or tooling mistakes.

This all-encompassing method makes it possible to quickly inspect the first article, check complex assemblies, and fix production tools with great accuracy. By using full-surface analysis, manufacturers cut down on inspection time by a lot and make sure that every part meets automotive quality standards.

Customization, design for the aftermarket, and adapting vehicles

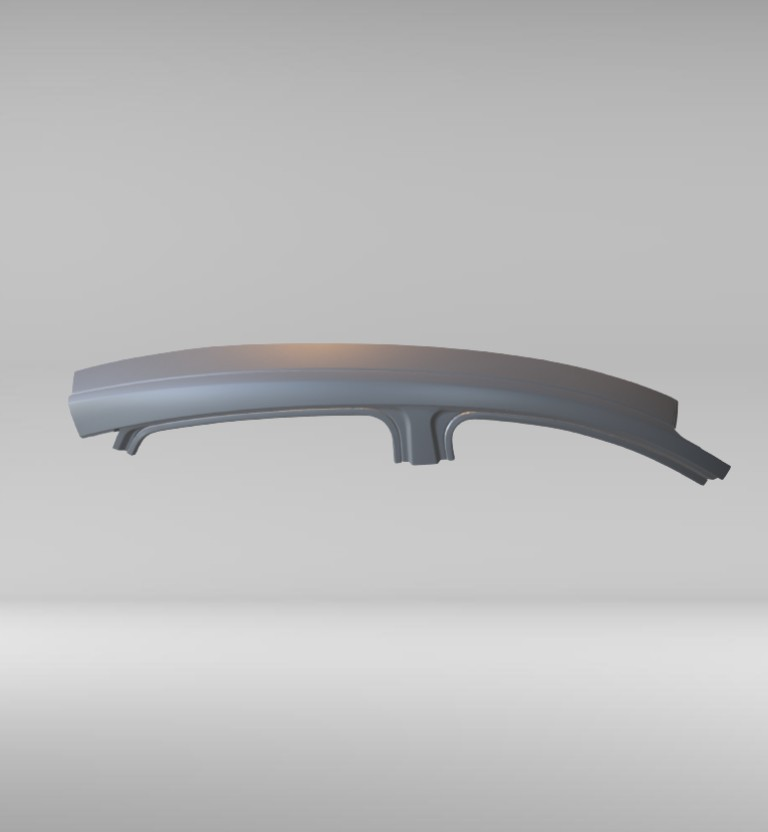

3D scanned models are very important for tuning vehicles, making custom changes, and designing aftermarket parts. These models capture the exact shape of the vehicle, making sure that new parts fit perfectly when making accessories like custom body kits, performance intake systems, or interior mounts. Traditional manual measurement can’t accurately reproduce the subtle curves of body panels or the complicated layouts in the engine bay.

The first step is to scan the target area, like a bumper or dashboard, to make an exact 3D scanned model. Designers then use this digital copy as a direct reference to make new parts in CAD that are sure to fit and work. This gets rid of the need for iterative physical prototyping, which saves manufacturers of custom and performance parts a lot of time and money.

Also, 3D scanned models make it easier to make more advanced changes to motorsport or restoration projects. Designers can make sure that new brakes, aerodynamic parts, or electronic accessories fit properly and have enough clearance by digitizing things like wheels, suspension, and chassis. This lets them customize the car in a very advanced way while keeping it safe and structurally sound.

Digital archiving and full documentation

Lastly, 3D Scan Models are very important for keeping a full digital record of the geometry of vehicles and manufacturing assets. In today’s factories, not only are the final parts scanned, but so are the tools and fixtures that were used to make them. Digitizing molds, assembly jigs, stamping dies, and composite lay-up tools makes a current and accurate archive. This Digital Archiving makes sure that if a tool breaks or needs to be replaced, there is a verified digital model that can be quickly and accurately reproduced.

For the vehicles themselves, making a complete digital archive of 3D scanned models of all the major parts makes it easier for manufacturers to keep track of and maintain them. You can use a digital twin of the vehicle to train people, write service manuals, and check that new models will work with old ones. It is an essential tool for keeping track of the complexity of vehicles and making it easier for design, engineering, and production teams to talk to each other. By collecting and organizing this geometric data, 3DeVOK solutions help car companies create an unbreakable digital record that makes paperwork easier, speeds up repairs, and guarantees the availability of parts in the long term. This makes the 3D Scan Model a permanent and important part of the automotive digital ecosystem.