In modern factories, Leadshine industrial solutions offer a practical approach to reducing operating and energy costs. As a trusted PLC provider, Leadshine integrates advanced industrial PLCs to enable precise control of machinery, minimizing energy waste. The MC516CS model provides local 6-axis pulse output and supports 16-axis EtherCAT bus control, allowing simultaneous management of multiple machines. With absolute and relative motion capabilities, facilities can optimize production sequences to avoid unnecessary power consumption. This positions Leadshine as a reliable PLC provider for companies seeking efficient and cost-conscious automation solutions.

Enhancing Flexibility and Control

A key advantage of the industrial PLC is its adaptability to diverse production needs. Leadshine systems support speed, torque, jog control, E-CAM, and interpolation functions, giving operators the flexibility to adjust operations dynamically. By matching Leadshine CAN bus drives and expansion modules, users can seamlessly extend control systems without increasing energy demand. Support for ST, LD, SFC, CFC, FBD, and IL programming languages ensures that operators can implement complex tasks efficiently, reducing operational delays and unnecessary energy expenditure.

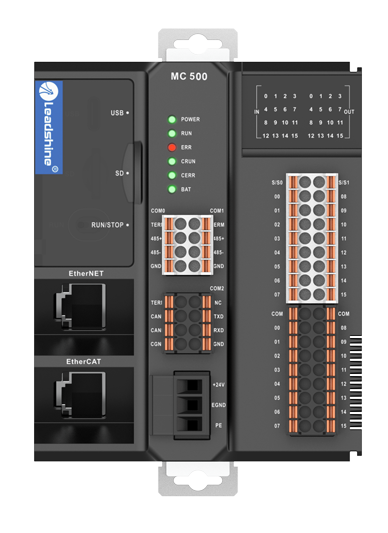

Seamless Integration and Peripheral Communication

Another feature that contributes to cost reduction is the ease of integration. The MC516CS supports 485 * 2 and 232 communication interfaces, making it straightforward to connect with peripheral devices. Local back panel BUS support allows up to 32 R2 series modules to be added, enhancing system scalability without extra energy costs. As a PLC provider, Leadshine ensures that industrial systems maintain high efficiency, reliable performance, and reduced idle power consumption across operations.

Conclusion: Reducing Costs Through Smart Automation

By implementing industrial PLCs from Leadshine, factories can achieve significant savings in both operating and energy costs. Features like multi-axis EtherCAT control, absolute/relative motion, flexible programming, and easy peripheral integration ensure optimized production and efficient resource usage. As a trusted PLC provider, they demonstrate that intelligent automation solutions not only improve productivity but also contribute to a sustainable, cost-effective industrial environment.